For choosing the number of keys depending on the diameters and of the load, as also for indicating the tolerances according to the desired fit loose, sliding, straining we refer to the tables published by the various standardization organizations:. Tools The new edition of DIN deals with fundamental principles, the same as its predecessor, but now also includes fit dimensions and tolerances, these being formerly contained in DIN Given these values, it is the designer's task to select the deviations and tolerance classes. With ever-evolving technologies and materials, the range of addressable applications across industries has never been so varied or offered such huge opportunities. Promoting, selling, recruiting, coursework and thesis posting is forbidden.

| Uploader: | Tern |

| Date Added: | 12 November 2013 |

| File Size: | 53.23 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 19622 |

| Price: | Free* [*Free Regsitration Required] |

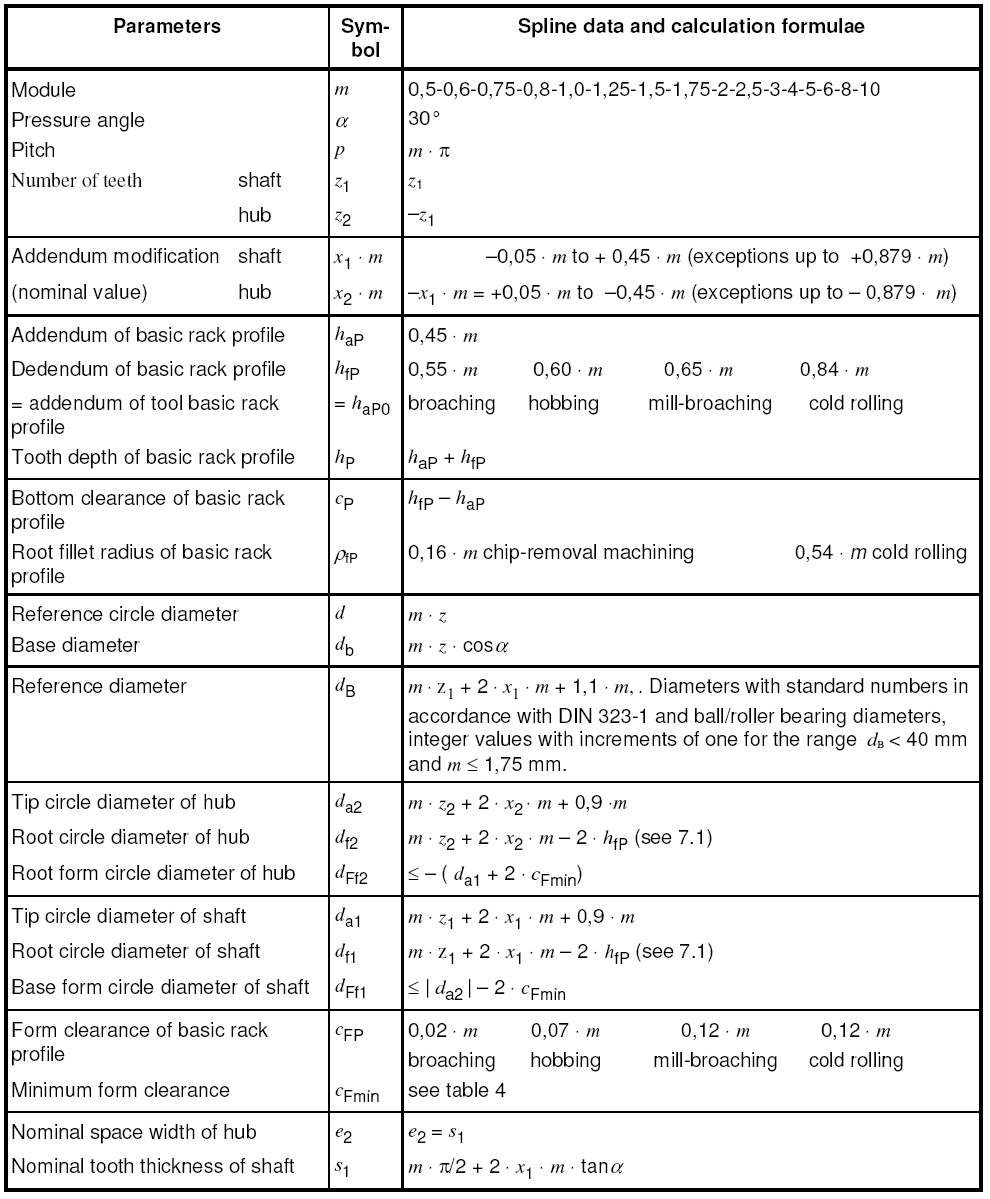

Key1 shaft2 hub3 profile reference line Figure 2: How did your program come up with x.

Din Male Spline Dimensions? - Gear & Pulley engineering - Eng-Tips

Are you an Engineering professional? DIN Table 2: Join your peers on the Internet's largest technical engineering professional community. Posting Guidelines Promoting, selling, recruiting, coursework and thesis posting is forbidden.

You can calculate the value of x from the equation: Principles Passverzahnungen mit Evolventenflanken und With ever-evolving technologies and materials, the range of addressable applications across industries has never been so varied or offered such huge opportunities.

Thank you for splie keep Eng-Tips Forums free from inappropriate posts. Since it is difficult to measure tooth thickness and space widths directly, they are converted to dimensions across and between measuring circles and are entered in this form into the data field.

WN2 / WN2+

The revision was considered necessary since a review of the DIN series of standards in accordance with DIN had shown that the series had structural and editorial weaknesses. External diameter centring 7.

They determine the design value of the connection diameter. I'm looking for male spline dimensions to make a shaft to fit a din female spline Nx5x30x38x9H.

Thanks for the post. Thanks for improving my post.

Download Now 3D printing is developing fast. Principles Splne mit Evolventenflanken und Bezugsdurchmesser — Teil 1: But if you want to learn more about DIN then I would highly recommend you download it. They are specs used to determine the type of fit called-for between the mating parts. Gearcutter, I have gone through the standard several times now. The magnitudes of the deviations are identified by upper-case characters and 21Uncontrolled copy when printed DIN can be selected individually for hubs and shafts as shown in table 9.

Thanks mate, so the 9g and 9H are not really the driving parameters for the profile shift?

DIN Spline Addendum Modifications - Gear & Pulley engineering - Eng-Tips

DIN defines the design features of tools for manufacturing items with involute splines. Are you an Engineering professional?

The only information we have about the shaft spline is W40x2x18x9g. DIN now contains the nominal dimensions and inspection dimensions for the range of items stated above. It's as gearguru says above.

Din Male Spline Dimensions? The fit and accuracy of concentricity are determined by the selected ISO tolerance fields of the centringdiameters.

Join your peers on the Internet's largest technical engineering professional community. This is necessary because the fit is created for all left and right flanks of all teeth. You have just one hub It lays downthe following fundamental principles: Read the Text Version. They determine the magnitude of the overall tolerance as well as the actual and effective individual tolerances.

No comments:

Post a Comment